Factors That Make Custom Embroidery Digitizing So Important

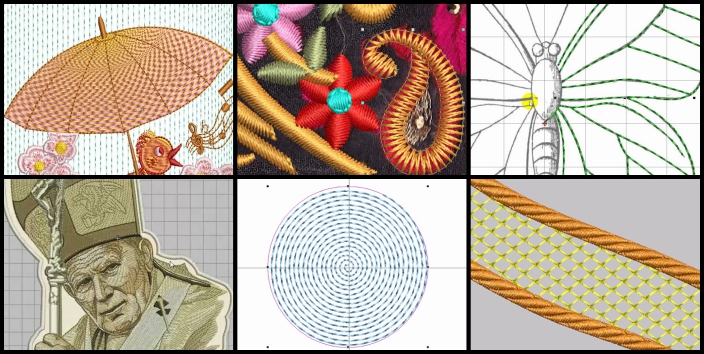

Embroidery DigitizingThe wave of digitization has traveled a long and deep pathway in the field of the garment industry. From the ancient human where clothes were just a means of covering the external appearance to the present-day digital world where apparels have become an epitome of status, style, and elegance, digitization has brought a massive and significant transformation. The same goes true for embroidery that was a beautifully handmade art during its inception and now a trademark for custom embroidery designs through computerized embroidery known to deliver elegant and inspiring masterpieces.

3 Key Factors That Contribute To The Growing Importance Of Custom Embroidery Digitization:

Individuality:

Custom designs always carry their own style, elegance, and attitude with the freshness and uniqueness of its elements and color combination.

Quality:

With embroidery digitizing, custom orders are known to be tagged with high standards of quality because every stage of the designing element is put under strict quality measures and guidelines to reach the maximum level of customer satisfaction.

Durability:

Custom embroidery digitizing with eye-catching designs and trendy style takes into account the quality of the embroidery design in a way that lasts long even under extreme weather conditions.

These 3 factors Are Based On The Following Parameters:

1 Allocation of Stitches:

The allocation of stitches takes place in accordance with the embroidery designs. The initial step for allocating is to understand the underlay stitches that define the process of creating a base on the fabric for all upper-layer stitches to fall down smoothly and flawlessly. It is just like creating a canvas on fabric to design a masterpiece. It is of utmost importance to have a defined structure for underlay and upper layer stitches. Even a slight inefficiency in creating the underlay stitches can cause to make the empty space of the fabric visible.

2 Types of Stitches:

There are mainly three types of stitches that fill the design elements depending on the chosen image and design. The three stitches include:

-

Satin

-

Fill

-

Run

The starting and stopping point along with the direction of each stitch plays an equally important role in digitizing. Experience and expertise in the field are best judged when a flow of design becomes pleasing to the eye with the right selection of stitches implanted in the right combination and direction.

3 Understanding Push and Pull Effect:

Understanding the push and pull effect is of great importance as this defines the intricacy and final finish of the embroidery design. During the embroidery digitizing, be it monogramming, appliqué work, or logo digitizing, fabric often tends to move from the place, and then the digitizer pulls it back to compensate for the stitch that often shifts from its place during the pull. This compensation if not done thoughtfully and precisely makes the final design look untidy and unappealing.

Selection Of Fabric

The selection of fabric is important because there is a direct connection between the density of the fabric and the type of stitch to be used on the same. It is always a joy to do embroidery on light and low-density fabrics like cotton and silk but when it comes to creating inspiring designs on heavy fabrics like denim, the task becomes tedious and challenging. Hence, there should be expertise to choose the right fabric for the chosen stitch. Still, if it is required to undergo an impossible stitch on high-density fabrics, none can perform it better than professional digitizers delivering quality embroidery digitizing services, who behold the expertise to adjust the design elements with the density of the stitch and density of the fabric.

There are many machines and software available for embroidery digitization. Some of the known machines are fabric inspection, profile cutting, fabric auto layering, waistband, welt pocket machines, and pocket facing. Moreover, the choice of software for computerized embroidery includes Wilcom E3, Brother PE, Embrilliance StitchArtist, and Embrid. The right selection of machines and software is the best way to deliver an assurance of quality and durability of the final output.

To conclude, custom embroidery meticulously following these parameters of designing is more in trend these days because of the prominence it delivers to the fashion world through its extraordinary quality, long-lasting durability, and a fresh breath of uniqueness to every piece of embroidered product.

An outsourced embroidery digitizing service agency can easily help you with this kind of output on almost any surface. This might sound very simple, but there are many techniques and methods that you should pay attention to when working on digitizing embroidery designs.